Concrete Water Storage Tanks. We Build 'Em Tough.

Looking for a Quality Concrete Water Tank?

Get It Built On-Site By Professionals.

Superior Quality Concrete Water Tanks

Use this section to describe the most important benefit of your product and make sure to describe it in such a way that it's clear who the ideal customer or user for this product is.

Underground Concrete Water Tanks

Terry specialises in building concrete underground tanks, and we have built hundreds over the past few years.

The largest of our heavy duty industrial concrete underground tanks will weigh approximately 78 tonnes when empty and you will be able to drive and/or park a truck on top.

We build these tanks with either six or eight support legs. With these support poles the roof of this tank will take up to 20 tonnes in load bearing weight and/or can take up to one metre of dirt/fill. We individually vibrate each leg in the tank to ensure the concrete is properly mixed. This is a very strong tank. You can use the top of the tank as a patio or bbq area; bury the tank completely or park your car on top! We use F92/F102 mesh in the roof of this tank, and Y12 starter bars in the base of the tank, which is why they are so strong.

Above Ground Water Tanks

Concrete water tanks keep your water cool under all conditions, are algae free and last for many, many years.

They will not rust, or burn or melt nor blow away, the water will not taint nor are there any inside liners to be replaced. And remember a decent concrete water tank adds value to your property!

The floors of the tanks are sloped into a 75 mm (3″) drain plug for above ground tanks and a sump for below ground tanks, which enables the tank to be cleaned out thoroughly.

And all required brass fittings are included in our price.

We can also supply at an additional fee safety ladders and platforms.

Concrete Water Tank Options + Fittings

We can supply and install all sorts of custom silo or colorbond roofs, access ladders, access doors and various sized inlet and outlet fittings to suit your needs.

Concrete Water Tank Repairs

Correctly built concrete water tanks will last for at least 25 years.

Recently, Terry was asked to repair an existing concrete tank which was built before Terry's time, nearly forty years ago.

Considering the age of the concrete tank, the tank was in remarkable condition.

Does your tank need some repairs? Call Terry to ask his advice.

Let Us Build You A Quality Concrete Tank.

Step 1. Site Preparation

Site preparation is the important first stage of construction of a Terry Miller Concrete Tank. Our tanks can be constructed either above ground or below ground. However, with any tank, the base of the tank needs to be flat, preferably laser levelled, with 150 ml of compacted road base, no fill.

Remember, a Terry Miller Concrete Tank is very heavy. This foundation should be of uniform thickness, preferably compacted road base capable of a safe bearing pressure of 100 kPa, with no fill.

There needs to be sufficient room around the base of the tank for the laying out of the formwork, building up of the scaffolding and vehicle access to the site, such as the concrete mix truck.

We recommend consulting with us about the site preparation to ensure the site is properly compacted and laser levelled and meets the required dimensions. That way we can fully guarantee your new Terry Miller concrete tank and avoid potential construction delays.

All Concrete work is carried out in accordance with the requirements of ASA Concrete Structures Code ASA 3600, ASA 3755 Concrete Structures for retaining liquids, and Building Codes B1 and B2.

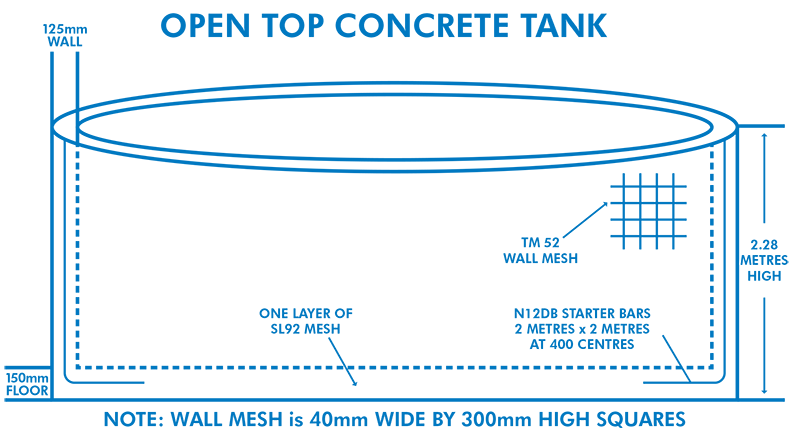

Step 2.a Above Ground Concrete Tank Construction + Roofing Options

All aspects of Terry Miller Concrete Tanks are built for strength, beginning with the assembly of the double layered mesh base with radial starter bars, through to the continuous pour, fully vibrated, 40MPa rated concrete.

All tanks have a base thickness of 190mm and walls that are 130mm thick.

Wooden blocks are used to support the inner wall of the base, so a seamless, continuous concrete pour is achieved, further strengthening our tanks.

These wooden blocks are removed when the floor of the tank is poured.

Heavy mesh and starter bars mean a stronger tank.

The quantity and strength of the mesh used is dependent upon the final load bearing weight of the tank. More mesh is used if the concrete top needs to take more weight.

Floor Mesh | Wall Mesh | Top Mesh | NL DB Starter Bars | |

|---|---|---|---|---|

Silo Roof | SL82 | WTM tank mesh | DB-12mm 750×750 | |

Concrete Top | SL92 | WTM tank mesh | xTwo layers of SL92 | DB-12mm 1500×1500 |

The largest of our industrial silo-roofed tanks will weigh approximately 44 tonne when empty. The silo roof is a proper heavy duty galvanised, pitched steel roof, not a flat roof. This roof weighs around half a tonne and a man can walk on top. This roof is rust proof.

The floor of the tank is sloped into a 90 mm (3.5″) drain plug, which enables the tank to be cleaned out thoroughly.

Above ground tanks are available with either a silo roof or an open top. We can also built, construct and erect colorbond roofs on request.

New replacement Silo roofs can also be made up to suit most concrete water tanks.

Insurance work is our speciality. We need to know the diameter of the tank and how deep the tank is. We can fit the roof for you or you can do it yourself. In our price we supply the metal sheets, the centre pole, which is hot tipped galvanised steel or stainless steel, depending on your requirements, dyna bolts, centre cone, disc and sieve. So ring Terry for a quote of what your new roof will cost.

Step 2.b Below Ground Concrete Tank Construction Details

All aspects of Terry Miller Concrete Tanks are built for strength, beginning with the assembly of the double layered mesh base with radial starter bars, through to the continuous pour, fully vibrated, 40MPa rated concrete.

All tanks have a base thickness of 190mm and walls that are 130mm thick.

Wooden blocks are used to support the inner wall of the base, so a seamless, continuous concrete pour is achieved, further strengthening our tanks.

These wooden blocks are removed when the floor of the tank is poured.

Heavy mesh and starter bars mean a stronger tank.

The quantity and strength of the mesh used is dependent upon the final load bearing weight of the tank. More mesh is used if the concrete top needs to take more weight.

Floor Mesh | Wall Mesh | Top Mesh | NL DB Starter Bars | |

|---|---|---|---|---|

Silo Roof | SL82 | WTM tank mesh | DB-12mm 750×750 | |

Concrete Top | SL92 | WTM tank mesh | xTwo layers of SL92 | DB-12mm 1500×1500 |

Our underground concrete water tanks are the perfect way to store water underground.

All our tanks are built with either 6 or 8 support legs depending upon the load bearing weight of the tank. Our standard tanks are built with 6 legs (load bearing columns), which will take up to 20 tonne of load bearing weight. This top will support a truck or car.

Airports, car wash yards, shopping centres, schools, hospitals all use underground tanks to store their water. Organisations do this to save on space, and not to detract from the look of their sites.

Terry Miller Concrete Water Tanks Underground concrete water tanks are perfect where lack of space is an issue. By being underground no above ground space is used.

The basic rating of 10 tonne half metre of dirt/fill can be placed on top. The flat surface of these tops can also be used as a patio/ barbecue area. If your requirements are for a heavier load-bearing top then this can be built as well, extra mesh is used to support the top in these cases.

The mesh used for the top of concrete tops is either SL92 or SL102 depending upon what load bearing weight is required.

The concrete top is supported by 6 load-bearing columns for the 20-tonne roof. These columns are poured at the same time as the top to enhance tank strength.

The floor of the underground concrete water tank is sloped into a pit, just offset of the manhole, which enables it to be totally emptied and cleaned out if need be.

Step 3. Enjoy Your Water!

Enjoy your brand new concrete water tank - for many decades to come!

Above Ground Concrete Tanks. Custom Options.

Check out the above ground concrete tanks options. Custom roofs, ladders, access and fittings.

Underground Concrete Tanks. Built Tough.

Check out this 30 tonne excavator on top of one of our 50,000 litre tanks; just one week after installation.

Get Your Own Concrete Tank Now

Contact Terry Miller and the team, today to get a custom quote.

Get In Touch.

Tap into Terry's 30+ years of concrete water tank construction experience and explore your tank placement and functionality options, to really understand your water storage and usage needs.

Get A Custom Quote.

After we understand your needs we'll send you a personalised quote for your new tank. It will cover everything you need to own the perfect concrete tank for your property and situation.

Construction Begins.

Once you accept our custom concrete tank quote, we'll schedule any ground works, and get started, so you'll soon be the proud owner of a brand new concrete water tank.